- [产品]-->大V型循环式筒子架

- [产品]-->KGAl 28超高速分批整经机

- [产品]-->回转式小V型筒子架

产品推荐

产品分类

联系方式

- 联系人:刘先生

- 邮 箱:llgp100@163.com

- 地 址:江阴市周庄镇科技工业园长寿工业园

- 手 机:13306162288

- 电 话:0510-86961001

- 传 真:0510-86961001

- 网 址:http://www.4fjki.com/

KGA163C型分条整经机

发布时间:2017-01-12

适用于精毛纺织物、化纤长丝织物、色织物、真丝织物及特种产业用纺织品等品种的分条整经。可作为剑杆、片梭、喷水、喷气等无梭织机的织前准备设备,是织造厂开发各种高档织物、特种织物的优选设备。

This machine is suitable for sectional warping all types of yarns,including worsted yarn,chemical fibre filament and silk It supplies rapier,projectile,water-jet and air-jet weaving machine with high quality weaver’S beams It is excellent in weaving top—g rade fabrics or special—type fabrics。

主要技术特征

1、整经和倒轴传动由交流变频控制,恒线速、恒张力、高速度运行。

2、专用机、电、液、气一体化的油压装置产生油压,推动钳式制动器,完成整经刹车控制:比例阀控制外钢带阻尼方式,实现倒轴张力的自动控制。

3、整经伺服传动采用双伺服电机滚珠丝杆结构,响应快,精度高,条定位和起点定位均一次按键自动完成。

4、交流数字伺服和滚珠丝杆传动的整经台前后移控制、并设有压纱辊、多种传感器。

5、整经过程中,整经台等距离后退。

6、伺服电机通过滚珠丝杆的传动多次测量整经纱层厚度,实现整经位移参数的自动测量(专利技术),压纱辊保证纱层面更加平整。

7、钢质大滚筒,并经高精度动平衡校验。

8、采用通讯技术,机、电、气、液、一体化设计。配置多套PLC、多套交流数字伺服变频、两套触摸屏,系统先进、可靠,自动化程度高。

9、整经主机在地轨上移动,分绞架和筒子架固定,使得条带相对于分绞架和筒子架中心不变,边纱张力均匀:

10、移动式倒轴机可与多台整经机主机配套,电、气通过插件连接,简便而可靠:单台时可固定安装。

11、配有多种型式的筒子架,锭距、锭数可根据用户要求选定。

12、备有多种形式张力器、断经自停装置供用户选配。

13、整经台上配有静电消除装置,倒轴机配有上油装置。

1、Warping and beaming is driven bv A .C. frequency converter so that constant yarn speed and tension is gained even at high speed.

2、The special machine ry—electricity—gas integrated oil pressure equipment can create o_l pressu re and d rive the clamPing breake r to

realize the contro…ng of warp break The proportioning valve contro the damping mode of the outer steel node and realize the automatic control

of the beam tension

3、Warp servo transmission uses the ball bearing lead screw structure and has the characteristic of rapid response.high precision Bar position

setting and initial,potential adiustment will complete automaticallY once button pressing

4、The forward and backward movement of warping table is controlled by AC diaital servo controller and transmission of ball screw rod The

system is also equipped with press roller and several kinds of sensors.

5、The warping table w…be backed for the same distance in the warping procedure.

6、Serve motor w…measure the thickness of warp th read for several times th rough the transmission of the ball bearing lead screw and realize

the automatic measu rement of the warping displacement The application of press roller to keep the flatness of the thread.

7、The steel d rum with fixed cone is precisely checked on inertial balance.

8、Mechatronics and automation is realized with a bus PLCs diaital A C servo controllers microcomputers with TTS(touching sensor screen)

and one long—distance monitor.

9、The warping frame is moved on the rail but the lease reed and creel is fixed so that the position of warp stripe is unchanged and the side

yarn tension is also constant.

1 0、The movable beaming pa rt can match one o r mo re wa rping machine The electrical SOU rce and ai r supply a re connected by the

inserter,simple and reliable.

1 1、Various types of bobbin creel are provided and according to the customer’s request spindle number and space are optional.

1 2、Several types of tension devices and stop motions are provided .

1 3、Static eliminato r is provided in the wa rping table and oiling equipment in the beaming part.

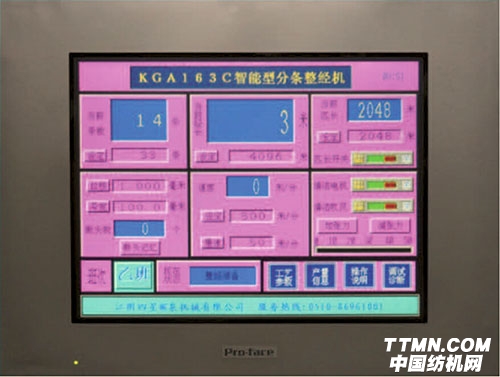

整经显示屏

Touching display screen