- 打印

- 字号

- 收藏

持续改进,增强客户满意度

上海强峰减速机械制造有限公司

公司名称:上海强峰减速机械制造有限公司

企业简介

我公司创建于一九九九年,由经验丰富的国营企业工程师所创建,技术力量雄厚,有多年生产摆线针轮减速机和ZLYJ硬齿面减速机的经验。它可广泛应用于矿山、起重、运输、化工、纺织、制药、食品等行业。质量保证价格优惠。

以客户为中心,法规为准绳;

持续改进,增强客户满意度;

以优质的管理为客户织造品质精良的一流产品。

Regard cystomer as center and code as yardstick;

Improve continuously,

Increase the satisfied content of customer,

Manufacture fine and top-ranking products for

Customers with quality management.

.jpg)

本公司是生产白线针轮减速机历史最悠久的企业之一。

“星浪牌”白线针轮减速机是采用K-H-V少齿差行星式传动原理及摆线针齿合的新颖传动机构。广泛应用于各种传动机械中的减速机构,如:化纤机械、纺织印染、轻工视频、冶金矿山、石油化工、起重运输、制药机械、电子通信及工程机械等领域中的驱动和减速装置。

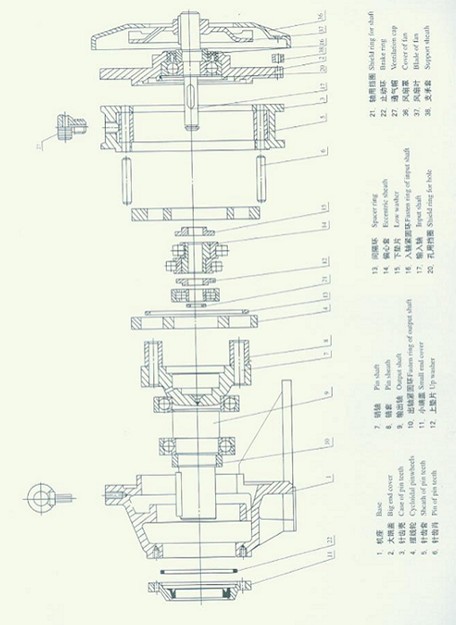

结构原理

行星摆线针轮减速机全部传动装置可分为三部分:输入部分、减速部分、输出部分。

在输入轴上装有一个错位180°的双偏心套,在偏心套上装有两个陈伟转臂的滚柱轴承,形成H机构。两个摆线轮的中心孔即为偏心套上转臂轴承的滚道,并由摆线轮与针齿轮上一组环形排列的针齿相啮合,以组成齿差为一齿的内啮合减速机构,(为了减小摩擦,在速比小的减速机中,针齿带有针齿套)。

当输入轴带着偏心套转动时,由于摆线轮上吃廓曲线的特点及其受针齿轮上针齿限制之故,摆线轮的运动成为既有公转又有自转的平面运动,在输入轴正转一周时,偏心

The company is one of enterprises that produce cycloi-dal pinwheel speed reducer with a long history.

“XINGLANG BRAND”Cycloidal Pinwhee; Speed Re-ducer adapts the principle of K-H-V planctary transmis-sion with les tccth difference and new style transmission mecjamos, of cucloidal pin-teeth joggle. It s wide used for speed reducing mechanism of all kinds of transmission machinery such as textile industry , dyeing and printing industry, light industry .foodstuff industry, metallurgy industry , mine industry . petroleum industry , chemical industry , chemical fiber machinery, pharmaceutical machinery, electronic communication, lift and transporta-tion industry cic.

Structural Principle

Its transmission dev

Double-eccentricity sheath with 180° dislocation is cquipped at output shaft. Two roller bearings called tuming arm are equipped at the eccentricity sheath. It forms Hmechanism. The central holes at two cyeloidal pinwheels are just the ball race of tuming arm roller bearings of eccentricity sheath. Meanwhile it is joggled with a ser of ring pin-teeth at cycloidal pinwheel and pin gear. In this way the inner jogg;ed mechanism with I different of teech is formed(In order to reduce friction, in speed reducer with small speed ratio the pin teeth is equipped with pin teeth sheath).

When input shaft brings eccentricity sheath to circumritate a cirele, because of the feature of up teetj contour curve of

.jpg)

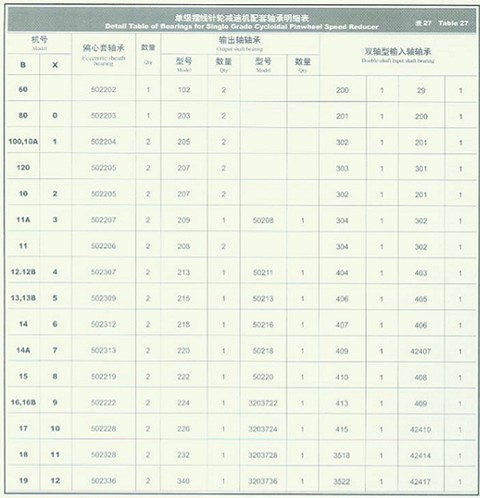

说明:(1)在双级减速机中各级转动比的组合,以高速端为传动比小的一端,低速端为传动比大的一端。

(2)双级减速机传动比-低速级传动比*高速级传动比

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

选择型号说明

(一)选择机号,请先确定一下三项参数

1.输入转速m(r/min)

2.转动比输出转速n(r/min)

3.输入功率P(KW)

(二)、如果输入轴的转速是变化的,则缩传递的功率也应是变化的,因

(三)、本样品的数据是按平衡载荷下,每日工作8小时,工况系数=1.0的计数值,而在选择机号时,即在确定减速机的输入功率时,还应考虑符合性质,工作条件及驱动动力源,以去定工作情况系数K。

减速机的输入功率按下列公式计算:P= K*P

N

其中:P ----- 减速机的输入功率

K-----工作情况系数

P2 --------被驱动机械所需的输入功率

n--------减速机的效率(单极为90%)

Explanation of choosing model

(一)When choose model,please decide the following tgree parameters

1.Input revolution n(r/min)

2.Ratio of transmission I or out put revolution n(r/min)

3.Input power P(kw)

(二) If the revolution of input shaft is changeable ,the power of trans-mission is changeable too. There fore when use variable speed tnolor or vari-able speed device to drive. Much attention should be paid to the selection of model. First decide whether the working condi

(三) The data in the catalogue is calculated in accordance with stable load. 8 bours of working time daily. Conefficient of working condition=1.0. When choosing , when decide the input power, it showld also consider the loding features, working condition and driving power source in order to decide the coefficient of working condition,K.

The input power of speed teducer should be Ealcalated in accordance with the following formula; P= K*P2

N

Where:

P------input power of speed reducer

K------coeffic ient of working conditio

P2-------needed input power of machinery to be driven

n-efficiency of speed reducer(for single polar,90%)

说明①最大瞬时载荷或气动载荷不超过额定载荷的160%

②原动机为多缸发动机时,数据表中的工作条件与载荷性质可选取K=1.0-1.7

③原动机为单缸发动机时,数据表中的工作条件与载荷性质可选取K=1.2-1.8

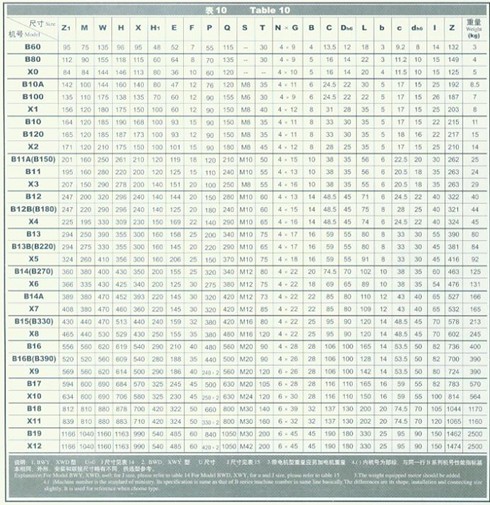

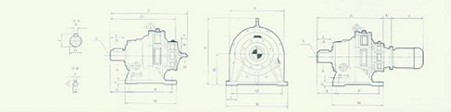

BW,BWY,BWD,XW,XWY,XWD 型单级摆线针轮减速机外形,安装和连接尺寸Outline, Installation and Connecting Size of Model BW,BWY,BWD,XW,XWY,XWD,Single-Grade Cycloidal Pinwheel Speed Reducer

BW,BWY,BWD,XW,XWY,XWD 型单级摆线针轮减速机外形,安装和连接尺寸Outline, Installation and Connecting Size of Model BW,BWY,BWD,XW,XWY,XWD,Single-Grade Cycloidal Pinwheel Speed Reducer

BW,BWY,BWD,XW,XWY,XWD 型单级摆线针轮减速机外形,安装和连接尺寸Outline, Installation and Connecting Size of Model BW,BWY,BWD,XW,XWY,XWD,Single-Grade Cycloidal Pinwheel Speed Reducer

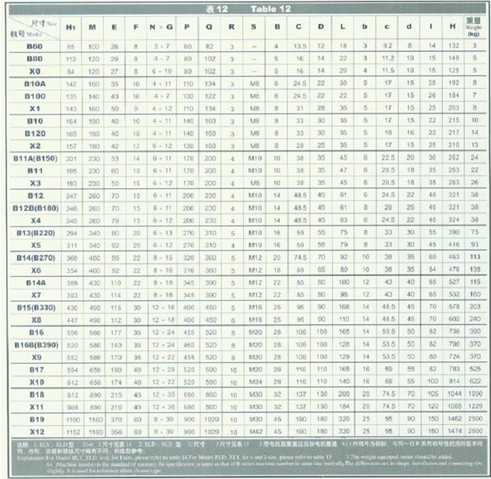

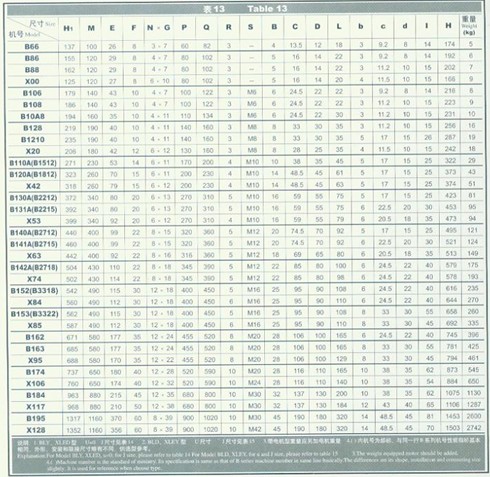

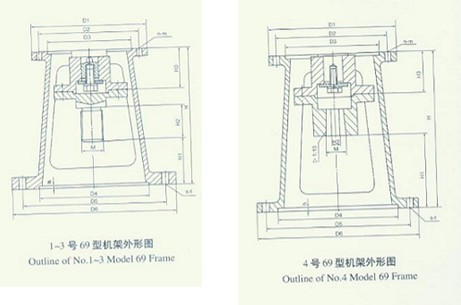

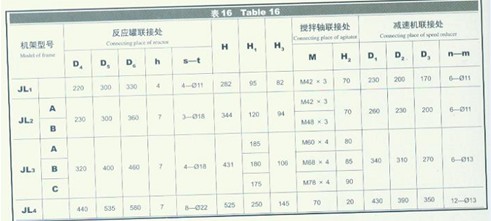

BL.BLY,BLD.XLE.XLEY,XLED型双级摆线针轮减速机外形、安装和连接尺寸Outline, Installation and Connecting Size of Model BL,BLY

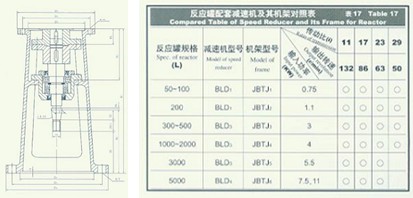

标反应罐配套摆线针轮减速机及其机架

79标反应罐配套摆线针轮减速机及其机架

为适应各行业特殊要求,我厂专门设计了多种特殊用途减速机,各种减速机内部参数等同于同类规格摆线针轮减速机,性能指标达到JB/T53324-1997的要求,欢迎各行业选用并为你提供各种非标产品的设计制造。

专为塑料挤出机配套的BJ,BJW系列减速机

In order to meet special requirement of different industry. Our factory has designed vanous special application speed reducer. The parameter of all kinds of speed reducer equals to cycloidal pinwheel speed reducer with same model. The property indexes reached the requirment of JB/T53324-1997. Sincerely welcome customers at different industry to choose and apply them. Our factory can also design and manufacture non-standard products for you.

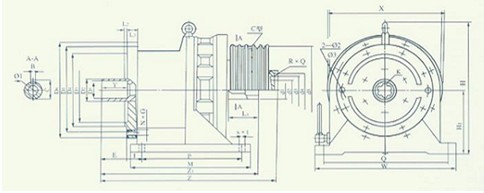

BK,BJW Series Speed Reducer for Plastic Extruder Specially

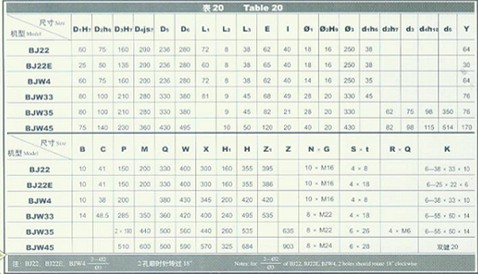

BJ系列外形及安装连接尺寸

BJW型外形及安装连接尺寸

使用

1.本减速机适用于24小时连续工作制,并允许正反向运转

2.单级减速机的出书轴

3.本减速机无自锁坐拥。

4.本减速机的输出轴不能承受轴向力。

5.在可能出现过载现象的适用场合,应安装过载保护装置。

6.脚板式卧装摆线针轮减速机要安装在没有振动、十分坚固的水平基础上,在必须进行倾斜安装的适用场合,减速机轴心线的倾斜度不得大于±15°

7.法兰式立装摆线针轮减速机在安装时,输出轴垂直向下。

8.如需要采用除脚板式卧装和法兰式立装以外的其它特殊安装形式,必须采取相应的润滑和密封措施来保证减速机润滑充足和防止漏油,请与我厂技术部门联系。

9.采用油脂润滑的摆线针轮减速机安装角度自由。

10.减速机安装时,可用垫块进行调整,垫块在高度方向不超过三块,也可用楔铁进行调整,但减速机校准后必须换入平垫块。

11.自爱冲击、振动较大或气动频繁的使用场合,机座与基础除用底脚螺栓进行联接之外,还需要定位销(自备)进行加固。

12.标准型摆线针轮减速机的输入轴和输出轴的轴伸端形式为圆柱形,采用普通平键联接。轴径尺寸公差根据GB1801-79《公差与配合》的规定。普通平键尺寸按GB1096-79《普通平键 型式尺寸》的规定,连接法兰止口按GB1801-79的(h9)配合。

13.当采用联轴器把摆线针轮减速机与相配套的机械联接时,推荐用弹性联轴器。

14.减速机与相配套机械用联轴器联接时,两者轴心线的同心度不得超过联轴器缩允许的范围。

15.当摆线针轮减速机与齿轮、链轮相联接时,必须保证两者轴心线的平行度。

16.当使用链轮来进行传动时,不要把齿链放得过松,否则在气动时会产生冲击力。

17.在把联轴器、齿轮、链轮等联接件联接摆线。

18.安装后的减速机,正式使用前必须进行试运转。在空载运转正常的情况下,在逐渐加载运转。

Application

1.The s

2.The rotating direetion of output shaft of single grade speed reducer is contrary to that of input shaft..

3.The speed reducer has no self-locking function.

4.The output shaft of speed reducer cannot undertake axial force.

5.For the applied field where may take place the phe-nomenon of overloading. It should be equipped with protee-tor of overloading

6.The pedal horizontal cycloidal pinwheel speed reducer should be installed the place where has no vibration and firm and level foundation. If it must be installed at the place where is incline, the incline extent of axial line should not be more than±15#.

7.When install flange vertical cycloidal pinwheel sp

8.If need other installing way except pedal horiontal or flange vertical. It must adapt lubricaitng and seal measures in order to guarantee that the lubrication of cycloidal pinwheel speed reducer is enough and prevent from oil leakage .Please contact with technical department of our factory.

9.The installing angle forcycloidal pinwheel speed re-ducer that adapts grease to lubricate is free.

10.When installation of seed redicer, it may adjust through filling block. The quantity of filling block at the di-rection of height should not be more than 3 pieces.It must be re-placed with flat filling block.

11.In the fields where has bigger vibration or frequency starting. Besides the base and foundation should be fixed with anchor bol

12.The form of shaft stretching end of input shaft and output shaft of standard cycloidal pinwheel speed reducer is cylinder. It is connected with ordinary flat key. The size tol-erance of shaft radial is in conformity with the regulations of GB1801-79:《Tolerance and matching》.For ordinary flat key size. GB1096-79:《Ordinary flat key form size》. For inter-face of flange. GB1801-79.(h9). Matching.

13.when use coupling to connect cycloidal pin wheel speed reducer and complete machinery, it is reconmentded to use elastie coupling.

14.When cycloidal pinwheel speed reducer is connected to it conmplete machinery. The concentricity of both axial cen-tral line should not be over that of the permitted range of coupling

15.When cycloidal pinwheel sp

16.When use chainwheel to connection . don’t let gear tooloosing. Otherwose ot can lead impacting foree when strat.

17.When the connecting parts suchas coupling. Gear. Chainwheel is connected to the output shaft of cycloidal pin-wheel speed reducer, it is prohibited to thump it directly. It should serew bplt through the screw hole at stretching end, then press it through pressing plate.

18.After in stallation. Before fomal operation. It must be dcbugged in idle. When ot os nprmal under idle operation. Then operate in load graducally.

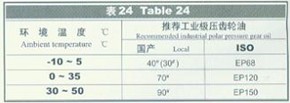

润滑 Lubrication

1.摆线针轮减速机的润滑方法见表21,表22。

2.法兰式立装摆线针轮减速机的润滑油泵见表23.

.jpg)

3.本减速机在适用前必须注入润滑油,出厂时减速机为了便于装卸和运输,一般都不注入润滑油。

4.采用油脂润滑的减速机在出厂前已注入润滑脂。

5.

6.当摆线针轮减速机在工作条件恶劣,启动,停止频繁和高温或底纹的场合中工作时,应与我厂技术部门联系。

7.当减速机采用油脂进行润滑时,推荐使用特种特种润滑----2#、二硫化钼-----2#或ZL------2锂基润滑脂等油脂。

8.加注润滑油时,油位高度应在油标或示油器的居中位置。

9.润滑脂的注入量应为减速机内腔容积的1/3-/1/2,油脂不宜加得过多,以避免产生搅拌热。

10.润滑油更换周期:

减速机应在初次运转300小时后须进行第一次更换润滑油,更换时,应去除残存污油。初次换油后,以后,每天连续工作10个小时以上的减速机,应每隔3个月更换一次润滑油,每天工作不超过10个小时的减速机,应每隔6个月更换一次润滑油。

11.油脂更换周期:每隔6个月更换一次。

12.已经长期没有适用的减速机(一般在12个月以上)在重新使用前,必须更换润滑油或润滑脂。

13.加油时旋开减速机上部的通气帽即可加油,放油时旋开减速机下部的油螺塞即可放出污油。

14.不允许注入不清洁或带腐蚀性的润滑油。

15.采用循环润滑油的法兰式立装减速机,在使用前应先启动油泵,待油泵正常工作后在启动减速机。

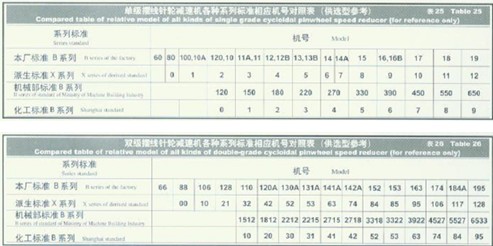

说明:不同系列标准相应机号,主要是指性能指标基本相同,外形,安装和联接尺寸略有不同。

减速机零件图

安装使用和维护

1. 减速器应安装在平整的基础上,在地脚螺钉均匀回转,以免给输出轴轴承增加附加应而影响轴承寿命。

减速器的输入轴以采用联轴器输入动力为宜。在安装时,应在地脚紧固的情况下,联轴器的安装误差不超过欧其规定要求。

当需要采用皮带轮输入动力时,以采用窄形高强度三角带传动为佳。这样可以缩短皮带张紧力的作用点的悬臂位置。三角带轮必需全部加工,回转平衡。三角带在初装状况下,不宜一次张紧(即张紧力过 大)。用户应在减速

由于硬齿面减速器的中欧高新距较小,无法配置较大的轴承,轴颈也较细,因此联轴器的对中与否和三角带张紧力,在输入轴悬臂端做用点的位置和大小将直接影响轴承、输入轴以至减速器的整机寿命!

2.在减速器安装完毕后,注润滑油至油标上油位,改油位应润滑油在箱内分布均匀后确定,油标位置,首次使用300-600小时后,应换油一次,以后每3000小时换油一次,更换应在减速器停车,润滑油尚未冷却时排放,箱内应用同品质的油冲洗干净。若因粘度高不宜冲洗,可先加热,滤清器一般每2000小时清洗一次。在出现油压下降,油泵噪声提高时,应首先检查滤清器是否堵塞,在拆卸滤清器时,应先将位于滤清器背面板式模块的截止阀手柄旋转90º,以截断油池与外界联接。

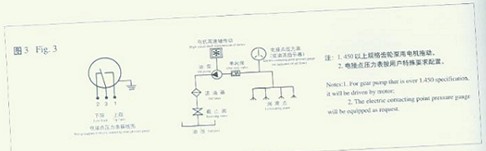

3.带电接点压力表的油路,压力表的上下限指针出厂前已调好,一般不用调整。如需调整时,可用随表的钥匙或螺丝刀,自爱压进表中心调整螺钉的情况下,加以调整。该表的输出接点见图3,用户可把此表接入电机控制回路或报警线路。当油路出现故障时,可自动报警,切断电源,及时检测维护。

4.装有油泵强制润滑的减速器,在开车初始截断,可能会因油粘度过高,油泵吸油阻力大而造成供油不足,发生过高的噪声,该现象一般在润滑油温度升高后,自行消失。

在正常运转中,如出现油泵噪声增高,一般情况可能是油路阻力过大。此时情况应清洗滤清器及其他相关部件。

无论哪种规格的减速器,在长期不用或气温过低时启动适用,都应控车运转一端时间,待各轴承处充分润滑后才可加载运转。

4.螺杆在安装时,应注意配合面和键的尺寸及粗糙度负荷图纸要求。不得采用强制力装拆螺杆,以免减速器在强力敲击下损伤。

联系方式

联 系 人: 敖思超

联系电话: 021-62567674

传真号码: 021-54310334

联系地址: 上海市静安区武定路595号2310室