江阴四星梶泉机械有限公司 |

|

| 联系人:刘先生 | 电话:0510-86961001 |

| 传真:0510-86961001 | 地址:江阴市周庄镇科技工业园长寿工业园 |

| 邮编:214400 | 邮箱:llgp100@163.com |

| 网址:http://www.4fjki.com/ | |

适用范围

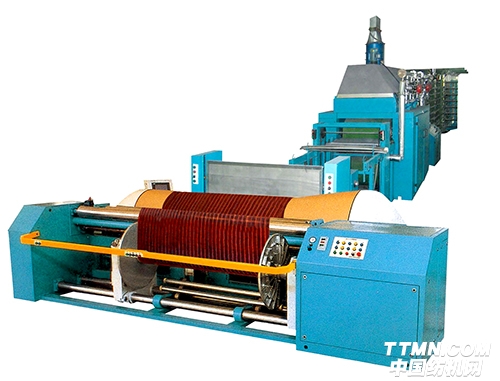

GA339型系列整浆联合机是纺织行业中织前准备设备,能满足毛、棉、麻、混纺等的色织及白胚织物的复杂的上浆工艺要求,结合了分条整经机和浆纱机的优点,将整经和浆纱工序合二为一,直接完成织轴的生产,该机器适宜小批量、多品种的生产,以及码样生产和新产品试制开发的浆纱、整经过程。具有纱线覆盖率底,浆膜完整性好,更换品种快、效率高、品质好,节约原辅材料,减少生产环节,降低生产成本。

本机对色织、毛麻、丝绸等行业各种原料的纱线从高支高密至低支低密甚至高支低密的特殊要求产品的工艺适应力强,通用性好。该机全电脑控制,设计合理,结构紧凑。技术先进,性能稳定、可靠,是各种剑杆、片梭、喷气织机的良好配套设备,是替代进口的良好选择。

In textile industry,GA339 type warping—sizing combination machine is the facility

for preparation before spinning It can meet the craftwork standa rd in sizing wool,

cotton,hemp,mixed fabric and grey fabric It has both advantages of sectional warping

machine and sizing machine,which makes warping and sizing completed once,and directly accomplish the production of beam GA339is suitabIe fo r smaII quaIity P roduction multiPIicity

production and sample production lt is alsO suitable for the sizing and warping process in new products research It has advantages of low percentage of yarn coverage,good integrity of chorion quick replacement of the older generation products by new ones,high efficiency,good quality,saving raw materials as well as supplemental materials,reducing production cost

GA339 is suitable to size and warp yarns used in color—woven fabric wool fabric silk fabric o r special industry fab ric.despite of the count and density Controlled by computer and structured reasonably the new technology machine is stable and reliable and canmatch with rapier,projectile,air-jet looms,etc.

主要技术特征:

1、微型计算机控制,触摸式人机介面,技术先进,操作方便,介面友好;

2、机、电、气、液一体化,技术先进、性能稳定、运行可靠;

3、先进的AC伺服随动系统,精度高,响应快,偏差小;

4、功能强大的微型计算机系统及先进的控制算法,使整个系统运行平稳、可靠,智能化程度高;

5、先进的AC矢量同步控制系统,同步精度高,响应快,超调小;

6、整经过程中不间断对各数据进行采样、分析、运算,使整个系统始终运行在最佳状态,使经纱成形平整,密度均匀,质量好,倒轴张力稳定均匀;

7、 浆槽采用双漫双压,品种适应性强;

8、气动加压,第二压辊线性加压,上浆率均匀稳定;

9、浆槽温度自控,槽体采用双夹层结构,保温性好;

1 0、主辅浆槽一体,逆流式循环,保持浆液粘度稳定;

11、采用全烘筒烘燥方式,分两组温度自控,效率高,适应性强;

12、烘房泵用积极传动,方便控制湿区伸长;

1 3、应用气液增压钳式制动,制动效率高。

1 Controlled by microcomputer touch human—computer interface advancedtechnology convenient operation and friendly interface:

2 Mechanical,electronic,gaseous,liquid integration,advanced technology,stable property.reliable running:

3 Advanced AC servo.high precision.quick response.1ittle deviation

4 Powerful function microcomputer system and advanced control methodenables the system running steadilyreliably and having high deg ree of intelligence;

5 Advanced AC vector synchronous controlling system.with high precision.quick response and low overshoot;

6 During warping course,constantly data sampling,analysis,calculation to keep the system in best condition make neat yarn figuration well_distributed

density,good quality,stable and well—distributed beaming tension;

7 Dual—dipping and dual—pressing_mode is applied to slurry tank

8 Pneumatic pressurizing and 2nd roller linear pressurizing ensures uniformstarching.

9 Self-controllable tank tempe ratu re double interlayer Of the tank ensures good insulation.

1 0 Integral main and assistant tank and countercurrent circulation ensures stable slurry viscosity.

1 1 Bake materials with full_enclosed drum It features independent temperature control of two sections.high efficiency and good adaptability

1 2 Active driving used On pump in drying cabinet makes wet area extension more easily

1 3 Applies air—hydraulic supercharging nip brake with high efficiency of braking.

主要技术参数 Main specifications

1.适用范围:6s一100s纯棉纱、涤棉纱、亚麻

2.整经有效幅宽:1800—3200(根据客户要求)

3.滚筒锥比:1:8

4.盘片直径:≤1 000(mm)

5.整经速度:2~1 00(米/分)

6.倒轴速度:0~1 00(米/分)

7.倒轴张力:≤6000(N)

8.位移精度:0.001(mm)

9.对条精度:0.01(mm)

10.位移范围:0.001~9.999(mm)

11.压浆压力:0~7.4kN

12.浆槽容积:主浆槽56(L)

辅浆槽51(L)

13.蒸发能力:180Kg/Hr

(蒸汽压力≤0.35Mpa)

14.装机功率:约40(Kw)

1、Application scope:6s一100s pure cotton yarn,terylene Cotton yarn.flax

2、Work width:1 800—3200 (according to Customer request)

3、Cone angle:1:8

4、Flange diameter:<1 000 (mm)

5、Warping speed:2—1 00 (meter/minute)

6、Beaming speed:0—1 00 (meter/minute)

7、Tension of beaming:<6000 (N)

8、Precision of displacement:0.001 (mm)

9、Paired bar precision:0.01 (mm)

1 0、 Displacement range:0.001—9.999 (mm)

1 1、 Squeezing pressure:0—560(kg)

1 2、Stock rough volume:main stock rough 56(L) assistant stock rough:51 (L)

1 3、Steam capability:180kg/Hr (vapor pressure≤0.35 Mpa)

1 4、 Installed power:about 40kW

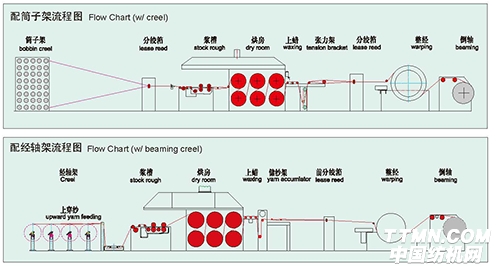

工艺流程示意图 Technological Flow Sheet

|

无锡二橡胶股份有限公司 |

常州市润源经编机械有限公司 |

|

青岛云龙纺织机械有限公司 |

黄石经纬纺织机械有限公司 |